Want to learn how to drill out a lock cylinder? Before you start drilling, place a center punch above the keyhole. After that, drill a hole through the cylinder of the lock. Drill again using a larger bit. Insert a flat-headed screwdriver inside the hole then turn it like you would turn a key.

You don’t need professional help to open your lock. This tutorial will guide you on drilling out lock cylinder. You just need to follow the steps carefully, and at the same time, use the items needed for the tutorial to successfully drill open a lock.

Table of Contents

What You Need

Before you can proceed with drilling a lock, you must first have the right items. Some of these items are commonly stored in a toolbox. If you don’t have them, you can purchase them at hardware stores near you or you can borrow from your friends or your neighbors.

What to Do

Step 1: Check if your lock can be drilled or not

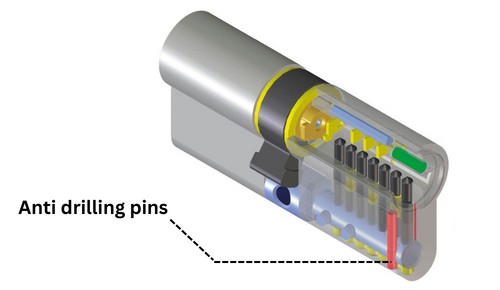

Before you start with the tutorial, you must make sure that your lock can be opened through drilling. If your tubular has a hardened steel center pin or a middle pin with a ball bearing, drilling is an ineffective method to open your lock. You can consult your lock manual to know the components of your lock.

Recommended post: Ways to drill out a tubular lock without spending too much time.

Also, check if other mechanisms could prevent you from opening your lock by drilling. If your lock has an alarm, it is recommended that you disable it to prevent your neighbors from thinking that there is a burglary going on.

Step 2: Place a center punch above the keyhole

A center punch will serve as a guide as you drill a hole. To prevent the drill from moving in the wrong direction, create a point below the shear line of the lock that divides the inner and outer cylinder. See to it that the point is high enough so you can successfully drill through the pin tumblers.

If you are not sure where the exact position is to create a hole, you can use a lock-drilling template to make things easier. You can usually purchase this kind of template in hardware stores.

Step 3: Drill a hole through the cylinder of the lock

You can now drill a hole through the cylinder of the lock to destroy the pins inside. You will feel a resistance when the drill bit reaches each pin. Typically, locks have five tumblers but others have six or more. In case the drill binds because of metal filings, you should put the drill into reverse then pull it out.

Prevent breaking the drill bit by not pressing too hard or working too quickly. When it becomes difficult to drill through the pins, you can stop and lubricate the drill bit with oil or water.

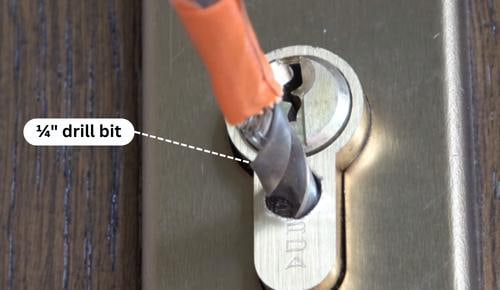

Step 4: Drill again using a larger bit

After you have drilled a hole using a small drill bit, switch to a larger bit so that you can destroy more pins so that you can open the lock successfully. You can switch into a ¼-inch drill bit or a larger one. Once you are done creating a bigger hole, you can proceed to the next step.

Step 5: Insert a flat-headed screwdriver inside the hole then turn it like you would turn a key

Insert the blade of the flat-headed screwdriver inside the hole that you made and turn it like you would turn a key. You will open the door if you have done the drilling correctly. In case the lock did not turn, you need to break the whole lock cylinder.

For you to destroy the entire mechanism of the lock, you need to switch into a larger bit. If you have a tubular lock, you will need a drill bit that is specifically designed for this kind of lock. Then, drill through the whole lock.

Conclusion

Do you enjoy our tutorial on how to drill out a lock cylinder? With these easy steps, you can open your lock even without your key. You can also follow this tutorial if you want to drill out a storage cylinder lock.

If you find this article helpful, you can share this post with your friends. This will also help them to open their locks in case of a lost key. You are also free to tell us about your thoughts and ideas as you do each step. Just leave a comment below.

I am the last member to join Revolar and might be just the luckiest to work with dedicated people like Teddy and John. Our team has established a process where my only job is writing the best content to deliver incredible ideas and guides.